Digital Die Cutting

Online printing with Smartpress is synonymous with high-quality materials, expert service and eco-friendly business practices. Included in that? Premium digital die cutting on our large format products.

If you’re creating projects like wall decals and car magnets and die cutting is one design option you don’t want to miss.

What is Digital Die Cutting?

So what do we mean when we say large format digital die cutting? It’s a process where a blade or router bit cuts large sheets of digital media into finished pieces on an industrial plotting machine.

In other words, it cuts your project into any size and shape.

For our online printing services, we primarily use a Zund digital die-cutting system to finish your product to perfection. Thanks to its Swiss engineering, the Zund executes with precision and speed. Other machines simply can’t match the functionality, quality or available tooling options.

Digital Die Cutting: Any Shape, Any Size, Any Time

With this premium feature, we’re not talking just simple circles, ovals or rectangles. Think any shape specific to your business or industry: abstract logos, wine bottles, food shapes for grocers, instrument shapes for school programs, etc.

Smartpress Tip: As you’re designing your projects, remember that the smaller your dimensions and detail, the more the die cutting quality decreases. For example, cutting finite detail inside a 1” x 1” square may be challenging depending on the thickness of the material and the level of detail required.

How Does Digital Die Cutting Work?

No matter what your project is, this feature produces the shape you need. Here’s how:

The Digital Die Cutting Process in 4 steps:

- A digital file of the cut paths and cut methods is prepared and sent to a server where it is called forward by one of our Zund operators.

- The file includes all directions and cut layers for each of the cutting methods specific to your job.

- The file also includes a register layer to orient the sheet placement on the cutting bed to the cutting beam and toolheads.

- Our operator uses a camera to locate the registration marks printed around the perimeter of the art and the cutting begins.

Die Cutting vs. Laser Cutting: What’s the Difference?

Digital die cutting and digital laser cutting are such similar terms, it’s easy to get them confused. The simplest way to differentiate them is by the cutting process.

As we mentioned above, die cutting is for our large format products and uses the Zund’s knife or router to cut them.

Laser cutting is for our small format products (business cards, brochures, cards, etc.) and features a MotionCutter laser digital die-cutting system. Here, the laser cuts paper stocks and other thin, flat materials.

Laser Cutting Pros

- Swift cutting method

- Fast job changeover

- Extremely precise

- Wide array of cut methods

- Can cut many different materials

- Lack of setup fees makes it a cost-effective design option

Laser Cutting Cons

- Can cut only one sheet at a time

- Limitations to thickness and density of some materials

How to Set Up Your File for Die Cutting

You may be asking yourself how should I set up my file for die cutting and laser cutting? Watch the video below to learn how in Adobe Illustrator or InDesign.

How to Add Digital Die Cutting to Your Project

You can add it to your project in two ways:

Option 1

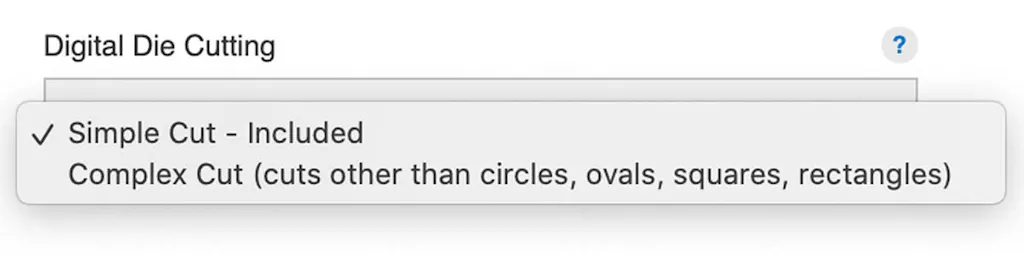

If you see a Digital Die Cutting dropdown on the product page (shown below), select which type of die cutting you’d like. Please provide a dieline of your artwork for specific shapes on your print-ready file.

Option 2

If you do not see a Digital Die Cutting dropdown on the product page, simply provide a dieline of your artwork for specific shapes on your print-ready file.

Tips & Tricks

- When submitting your print-ready file, a clean, minimal vector point dieline is best.

- The cut itself can become choppy if too many points are used to create a vector dieline.

Die Cutting vs. Laser Cutting Key Takeaways

| Digital Die Cutting | Laser Cutting | |

| Cutting Method | Blade or router (mechanical) | Laser beam (thermal) |

| Materials | Thicker substrates, rigid boards | Paper, thin vinyl, flat lightweight materials |

| Used For | Large format products (e.g., decals, signs) | Small format products (e.g., business cards, brochures) |

| Precision Level | High, but limited with very small/intricate cuts | Extremely high, ideal for fine details |

| Design Flexibility | Any shape possible; limited by material thickness | Highly flexible; better for delicate or small designs |

| Speed | Fast for bulk jobs; can cut multiple layers | Fast but cuts one sheet at a time |

| Setup Requirements | Minimal setup; dieline required | Minimal setup; no physical dies needed |

| Limitations | Small, intricate details may degrade quality | Limited by material density and thickness |

As a world-class online printer, we try to make the whole digital die cutting process as easy as possible. If you have questions about this or any of our products and services, please contact customer service.