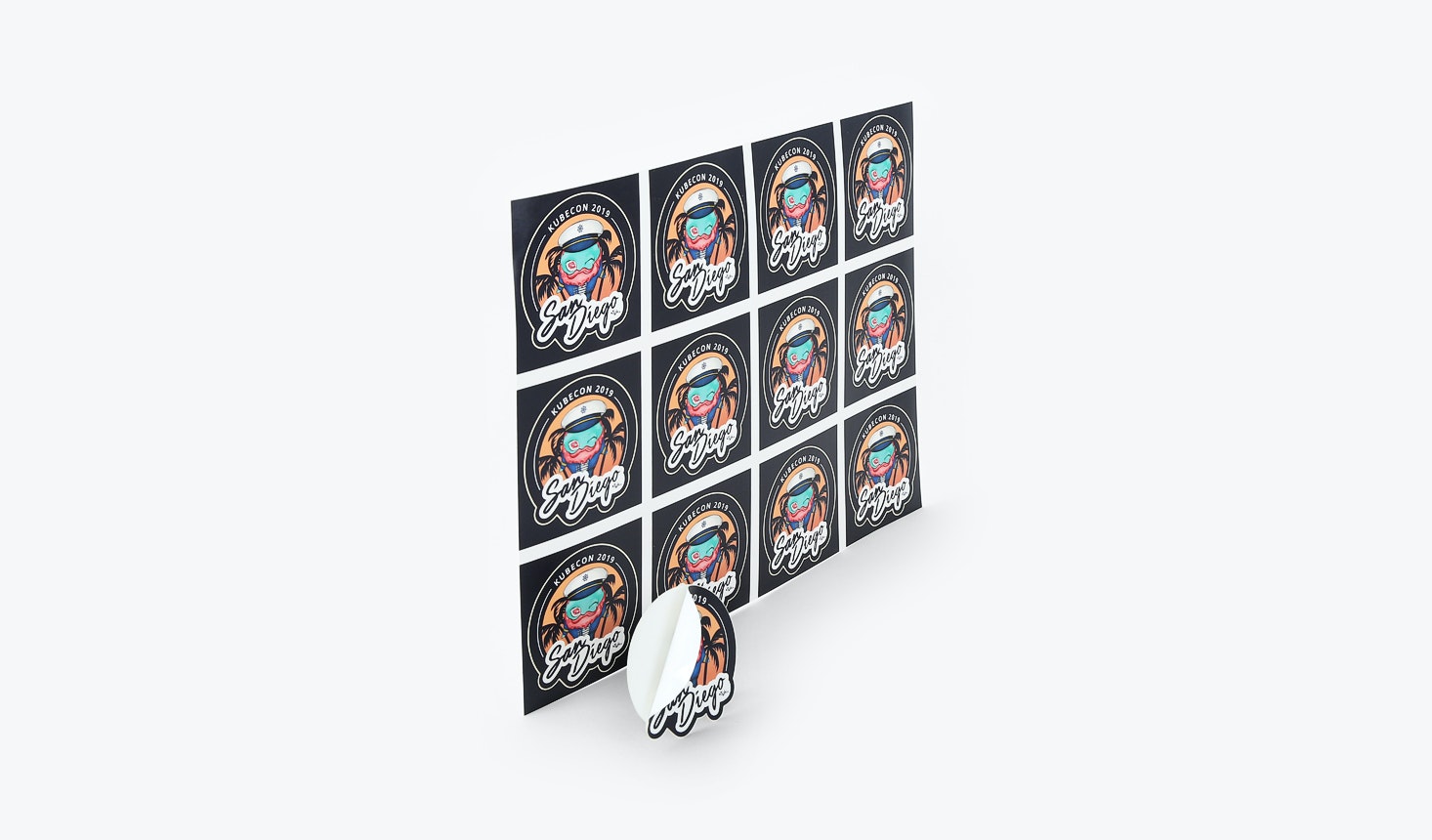

Sticker Printing

Creating and printing stickers is so fun and easy with Smartpress’ customizable, cost-effective options. There are multiple sticker printing substrates for almost any need, and when you add digital laser cutting, they can be produced for online printing in any shape you like.

Variable data printing, sequential numbering, rounded corners and shrink wrapping can all be used to personalize your stickers for marketing, promotions, direct mail and more.

Before you upload your design to an online printer, learn more about the sticker printing options below and choose the best one for your project.

Sticker Printing Substrates

60# Matte Crack ‘n’ Peel

- Our Crack ‘n’ Peel is a 60# coated matte paper sticker stock with permanent adhesive and a split back liner.

White/Clear Polypropylene Permanent

- Permanent sticker stock is made of top-coated smooth flexible polypropylene. These stickers are repositionable and intended for one-time use.

- Permanent stickers are suitable for textured materials, such as paper or T-shirts, and will not damage the surface to which it is adhered. Other applications include rigid plastics, films, glass and painted metals.

White/Clear Polypropylene Removable

- Removable stickers are made of top-coated smooth flexible polypropylene. These stickers are repositionable and retain their stickiness when moved from surface to surface with good chemical resistance. They are low-tack and moisture-resistant with good chemical resistance.

- Temporary stickers are recommended for a variety of uses on non-textured surfaces, such as glass, painted metal and stainless steel. They’re removable even from paper!

White/Clear Vinyl Removable

- Removable vinyl stickers are the same as removable polypropylene stickers with one exception. They cannot be digital laser cut and are available only in square or rectangular singles.

- We strongly recommend full color + spot white or white-only ink for clear substrates so the print is vibrant and less translucent.

Cutting Options

Non Digital

- Stickers can be cut in basic squares and rectangles and can measure 2” x 2” or larger.

- Laser die cutting is much less expensive than traditional methods because there is no need to create expensive metal dies for individual projects. Instead, a laser simply traces the die line on the paper, removing the material and leaving a smooth precise cut.

- There may be very minor discoloration along the cut that may be visible on white or light-colored designs. To avoid this, the distance between cut lines must be more than three points and the die line must be supplied with your artwork.

With digital laser cutting, you can print stickers in any shape and size. Just select your preference in the Shape and Cut Type dropdowns on the product page. Options include:

- Cut-to-Size (Die Cut): A single sticker die cut to the shape you’ve specified (circle, oval, square, rectangle or custom).

- Peel-Off from Liner (Kiss Cut): A single sticker cut on the dieline with an additional die cut about 1/4” around to allow for easier removal from the sticker liner.

- Sheet: Single Design: This cut gives you multiple stickers per sheet with one cutting design/shape.

- Sheet: Multiple Designs: This cut gives you multiple stickers per sheet with different designs/shapes. (Only available when ‘Custom’ is selected in the Shape dropdown.)

Learn more: Sticker Printing FAQ, Custom Branding: Print Labels, Stickers & Decals for Products & Packaging