Dot Patterns

What are Dot Patterns in Printing? How Do They Affect Print Quality?

In the online printing world, “dot” refers to the pattern of dots that simulate a continuous tone image with solid ink. However, most modern printing technologies simply can’t produce these tones to create dot patterns.

Instead, this article explains how an online printer can produce printed images that contain a series of dots in specific patterns and these patterns simulate shades of gray.

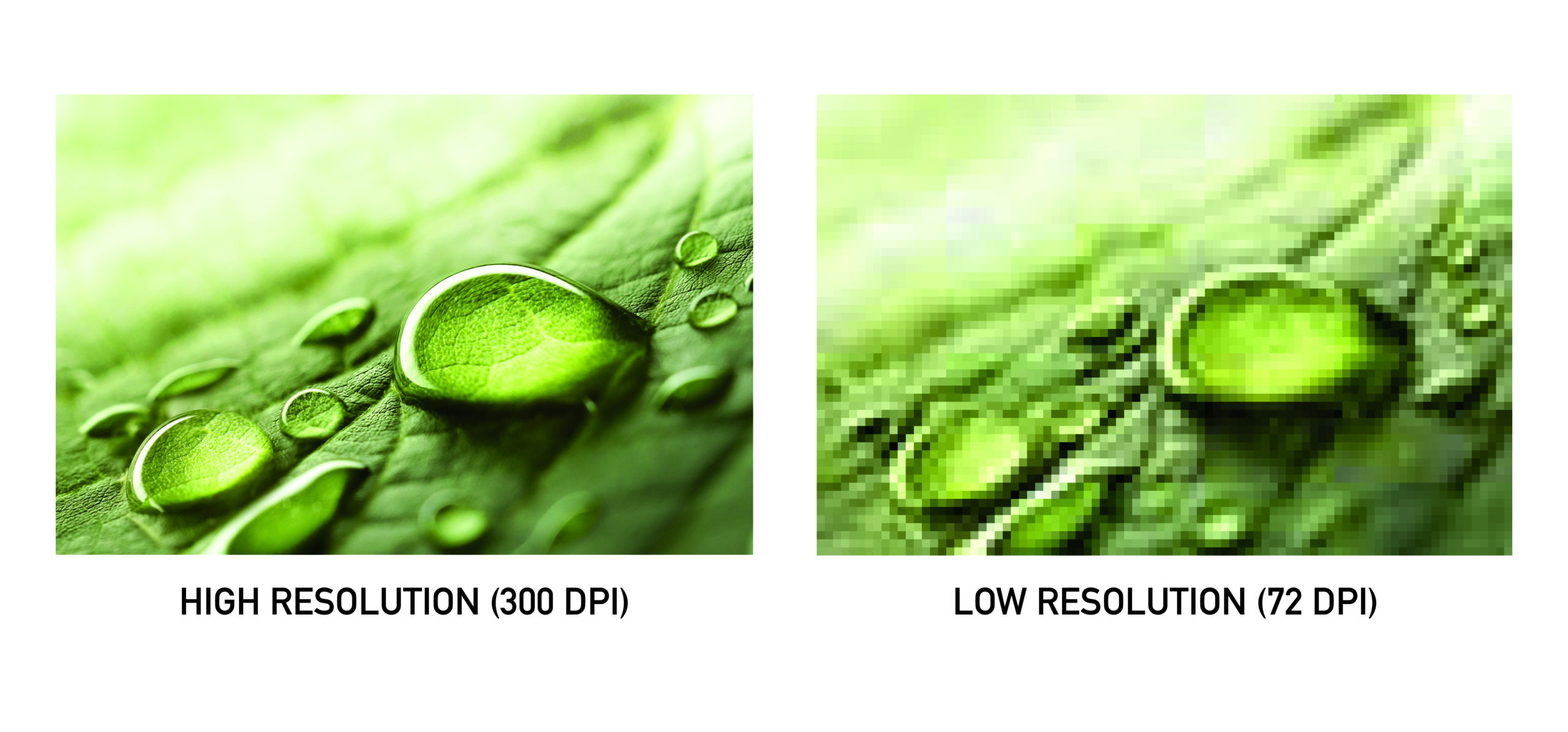

Smartpress’ small format digital printing presses are at the cutting edge of technology, achieving 1600 dots per inch (DPI) resolution, surpassing the quality of offset printing. This provides optimal smoothness on photo and high-end commercial applications.

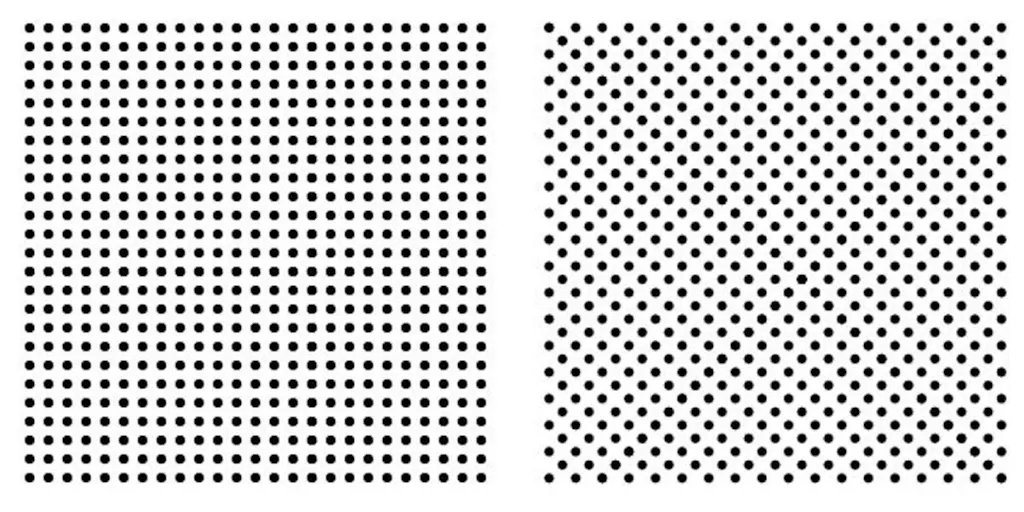

What are Halftone Dot Patterns in Printing?

It’s important to note there are certain prints that may show dot patterns in halftones (creating a gradient-like effect), which is normal and can be expected.

A black and white halftone image consists of a single screen. In the example image showing a halftone screen at 0°, the dot pattern is clearly visible. When rotated to 45°, the pattern appears more blended and less noticeable.

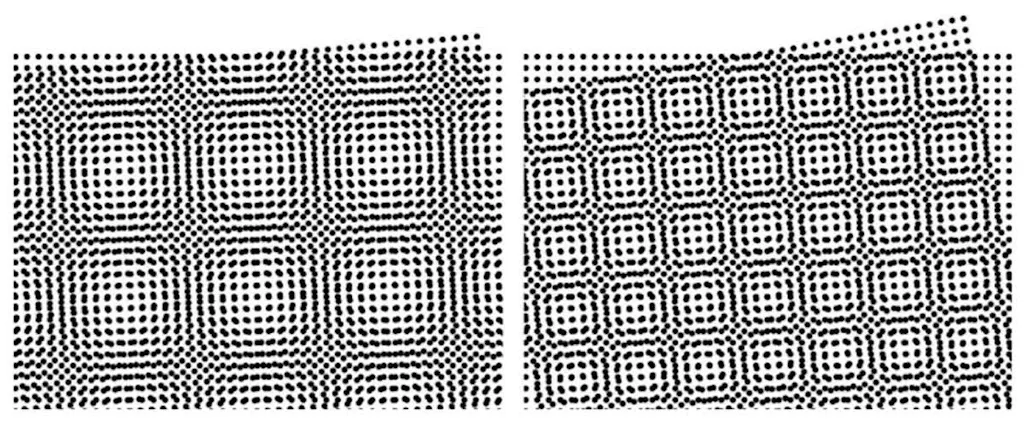

What Causes Moiré Dot Patterns and How to Avoid Them

A moiré occurs when multiple screens are printed on top of each other and the dot patterns don’t line up. Moiré patterns that are most difficult to look at occur when the screens are off by very small angles.

Smartpress Tip: The best angle for two or more screens to be overlaid is 45°. You’re least likely to have patterns result in moiré and 45° is the most forgiving angle for small errors.

In the images below, you’ll see two halftone grids with overlaid angles at 5° and 10° apart. The moiré pattern is impossible to miss:

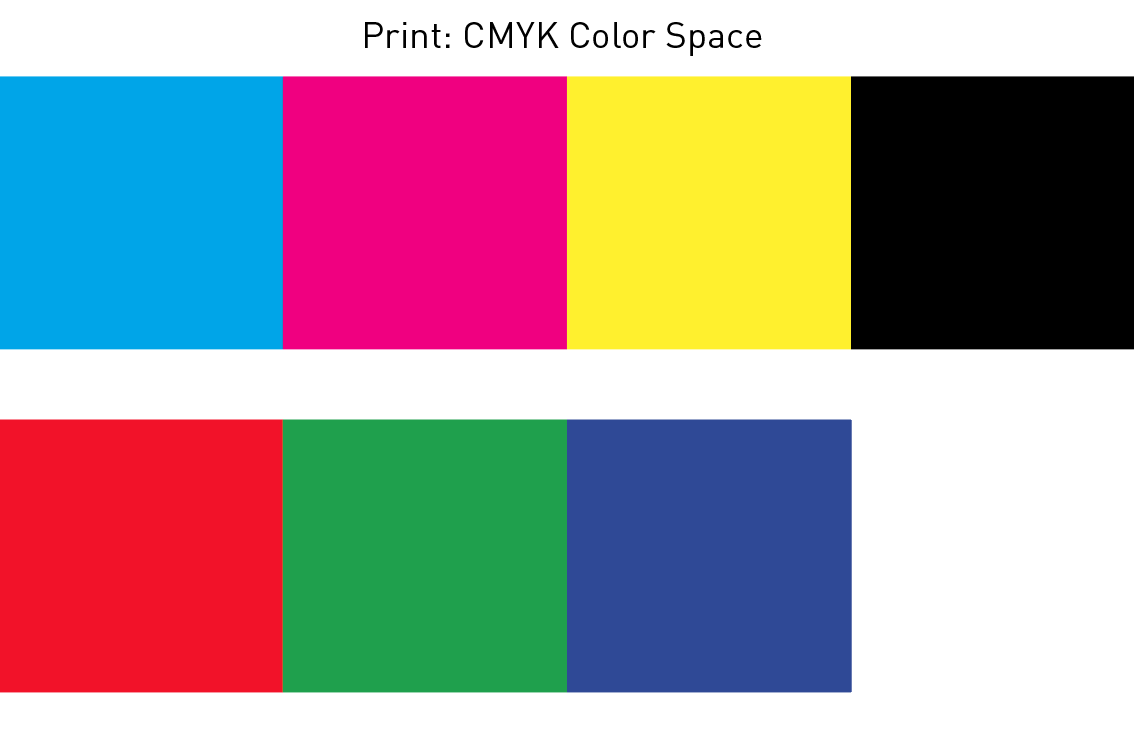

How Four-Color Process Printing Uses Dot Patterns

In four color process printing, four different screens are superimposed onto each other. These screens are also angled within the 90° limitation.

Because of this, the cyan, magenta, yellow and black screens must be overlaid at varying angles to result in the moiré that’s least offensive, as shown below:

When it comes to dot patterns, the presses we use feature stunningly high resolution and carefully calibrated screen angles that exceed the industry standard. And it’s all part of our premium online printing services. If you have concerns regarding moiré in your print, please contact your account representative. If you don’t have a rep, feel free to contact customer service.